Unicomp X-ray Testing Equipment Promotes the Development of Lithium Battery Industry

Author: Unicomp Technologyissuing time:20 May,2021Viewers:408【SML】

Nowadays, with the rise of energy and oil prices and the advance of electric battery technology, there are all kinds of lithium batteries from mobile phones, electric cars to buses and automobiles...

Text labels:

Nowadays, with the rise of energy and oil prices and the advance of electric battery technology, there are all kinds of lithium batteries from mobile phones, electric cars to buses and automobiles.Today, our lives are inseparable from lithium batteries. In order to obtain high quality lithium battery products, it is necessary to improve the production level of lithium battery. Lithium-ion batteries are prone to defects, such as scratches in the production process, which seriously affects the quality and service life of the battery. Unicomp Technology provides professional testing products and services in the manufacturing industry in China, and has proven the use of X-ray testing equipment to test inner defects to achieve good results in lithium battery testing.

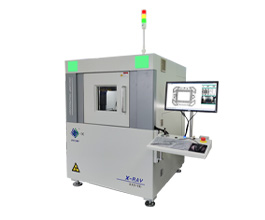

Unicomp X-ray lithium battery test equipment AX8800 is a new X-ray test equipment with high performance, high definition and high resolution. The camera has a small opening angle of 60° rotation tilt, CNC program operation detection, automatic measurement, information security identification system, and radio energy monitoring system for automatic program detection and automatic judgment of lithium battery.

Advantages of using X-ray equipment for lithium battery testing: X-ray testing can accurately identify scratches, electrode welding asymmetries and other defects without disassembly of the sample. And the accurate rate is much higher than that of human eye detection. When using X - ray device to test lithium battery, the influence of subjective factors on battery test results is not included, and the results are more objective. X-ray inspection is an optical non-contact defect inspection that can be used to mark or reject defects on the lithium battery stem and automate lithium battery inspection.

Unicomp has full range inline automation X-ray solutions for Cylindrical Lithium battery, Polymeric Lithium battery, laminated lithium battery and Power Cell Lithium battery. It has more than 100 systems were installed in Tesla, Northvolt, Panasonic, Sony (Murata), A123, CATL, BYD, GuoXuan, Sunwoda, BAK, EVE Power and others well-known customers.

How Unicomp Lithium Battery X-Ray work to inspect:

To know more about Unicomp Lithium Battery X-Ray inspection system, please feel free to contact us by email:marketing@farragutfest.com or visit our website: www.unicompxray.com

20 May,2021

408People browsing

Back

Mobile Website

Mobile Website